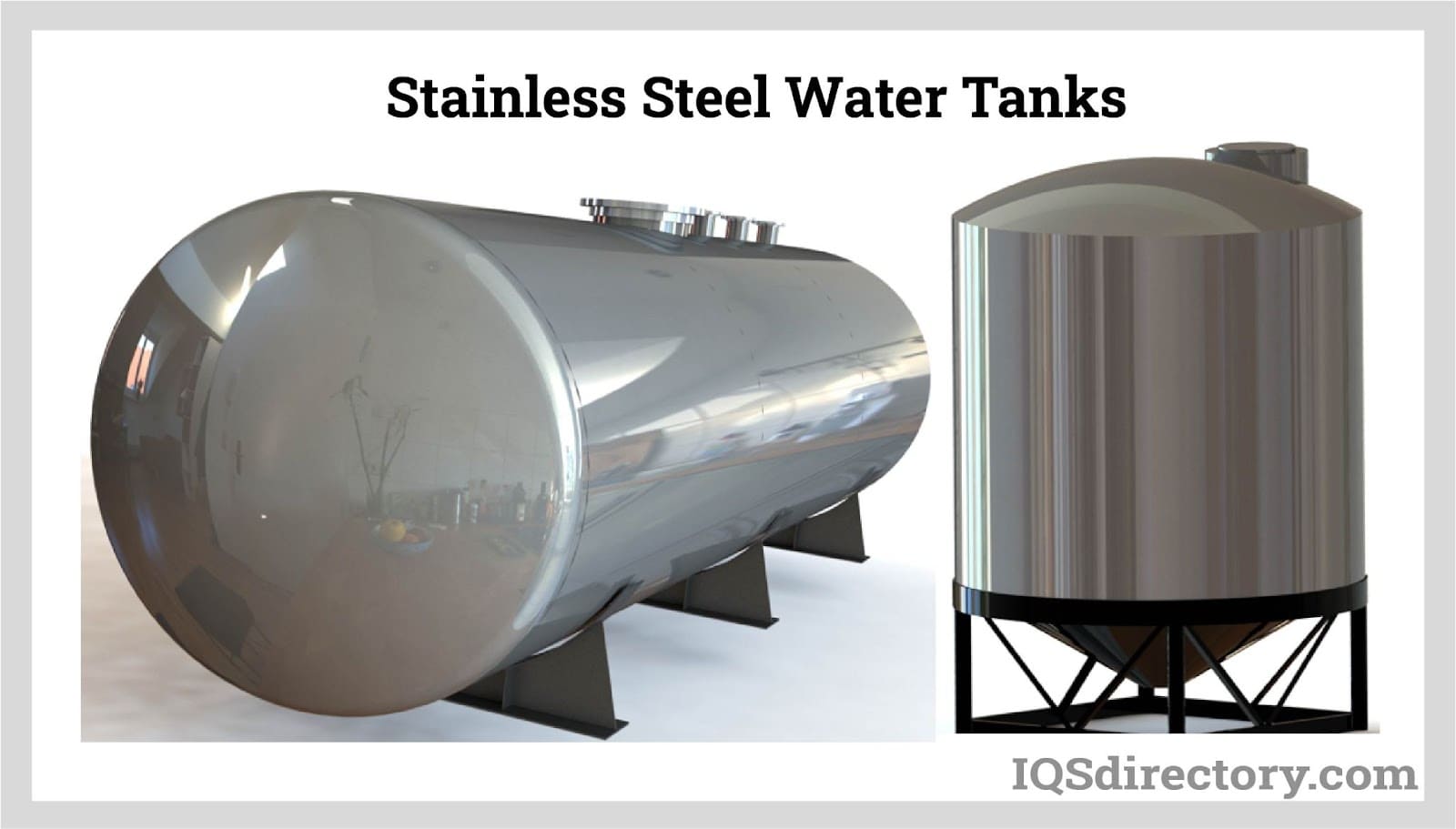

Stainless steel water tanks are the best choice for storing drinking water. These tanks are durable, easy to clean, and require less maintenance. However, stainless steel water tanks are not always best to use because they are expensive and can corrode in extreme conditions. Water tanks made of galvanized steel are prone to rust; tanks made from stainless steel are corrosion-resistant but expensive to install and require maintenance to avoid rusting. Read More…

Here at Frain Industries, Inc. we offer an extensive line of stainless steel tanks. These tanks come in a wide range of shapes and sizes based on their application. Our tank sizes range from 5 gallons to 10,000 gallons and these tanks can be customized to meet your application needs.

For 50 years G & F Manufacturing has been a leading quality stainless steel tank manufacturer for many industries, including pharmaceutical, food & beverage. Their storage containers offer quality workmanship & durability.

At True-Blue Welding and Fabrication LLC, we pride ourselves on our expertise in crafting high-quality stainless steel tanks. Our journey is defined by a relentless pursuit of perfection and a commitment to meeting the diverse needs of our clients. Join countless satisfied clients who have entrusted us with their most demanding projects and experience the True-Blue difference today.

At Bendel Tank & Heat Exchanger, we have built our reputation around the design and fabrication of stainless steel tanks that serve a wide range of industrial applications. We bring decades of expertise to every project, combining precision engineering with advanced manufacturing techniques to deliver tanks that meet the strictest performance and safety standards.

At Vector Systems, we specialize in designing and fabricating high-quality stainless steel tanks engineered for durability, performance, and long-term value. Our team brings together decades of experience in fluid handling systems and precision metalwork, allowing us to meet the strict requirements of industries ranging from chemical processing to food and beverage production.

At Silver State Stainless, we take pride in our expertise and innovation in crafting stainless steel tanks tailored to a wide array of industrial applications. Our commitment to excellence is reflected in the comprehensive range of products and services we offer, all designed to meet the exacting standards of our diverse clientele. Our stainless steel tanks are engineered with precision and built ...

Midwest Tank Company has provided quality tanks to small and large corporations and contractors since 1972. Our reputation is built on exceptional services and customer satisfaction! Our fabrication techniques have been developed through years of tank specialization, combined with personnel who are experienced in all phases of our operation.

More Stainless Steel Water Tank Manufacturers

Why Stainless Steel Tanks are Popular

Stainless steel is a popular material for making tanks. Stainless steel comes in a variety of grades and types. Each grade and type has its own unique properties and characteristics that are used in different applications. Stainless steel tanks are popular in the tanks industry due to the following properties:

- Stainless steel offers durability and great corrosion resistance compared to other materials. This makes it suitable for making tanks that need to store water or any other corrosive material.

- Stainless steel tanks are durable and offer resistance to wear and tear. Moreover, they are not damaged by radiations or harmful chemicals.

- Stainless steel water tanks are hygienic. These tanks do not allow bacterial growth and molds, making the water clean and pure to use.

- Tanks made from stainless steel are recyclable and environment friendly.

- Stainless steel tanks are more appealing to the eye than plastic or concrete tanks.

- Stainless steel tanks have better tensile strength than tanks made from other materials.

- These tanks are easy to maintain and clean.

Components of Stainless Steel Water Tanks

A stainless steel water tank is used for domestic and commercial use everywhere. Good-quality tanks are important to ensure the safety of people using that water for different purposes. Stainless steel water tanks vary in size, shape, and capacity depending on the purpose they are being used for. Following are the components of a stainless steel water tank:

Inlet and Outlet

The inlet and outlet of water tanks allow the entry and exit of water. Proper placement is necessary for both of these. The inlet should be on the top of the tank for maximum intake of water, while the outlet should be at the bottom of the tank. It is necessary to properly circulate the water inside the tank to avoid contamination.

Overflow Pipe

The overflow pipe is placed on the inlet of the tank to avoid water overflow; otherwise, the tank will burst from excessive pressure.

Drain

The drain is located at the bottom of the tank to remove residuals after cleaning.

Shell

The shell, or cradle, of a stainless steel tank keeps the shipment safe and secure.

Vent

Vents are located on the top of the water tank to release air from the tank. The vent pipes are placed in a downwards direction to prevent any unwanted particles from entering the tank.

Level Indicator

A level indicator is a rod placed inside the tank to keep an eye on the level of water stored in the tank.

Sump

A sump is placed at the bottom of a stainless steel water tank for drainage purposes. If the water tank is underground, an additional sump is required.

Manhole

A manhole is located at the top of the water tank for cleaning purposes. Maintenance and inspection of the stainless steel water tank are conducted through the manhole.

Tankheads

Tankhead details like the style, dimensions, and polish are done prior to shipment of the tanks.

Types of Stainless Steel for Water Tanks

Stainless steel grades 304 and 316 are generally used for manufacturing water tanks. Both these grades are suitable for storing and handling domestic cold or unheated water. If the water tanks are properly maintained and cleaned, there are less chances for corrosion in the tanks.

However, hot water tanks are prone to stress corrosion cracks. Certain factors affect the water tanks such as extreme temperatures, chlorides, and oxygen levels. Chlorides and temperatures can be controlled by treating and fabricating the water tanks with certain processes.

Austenitic stainless steel materials are more prone to these corrosive attacks; therefore, alternatives such as ferritic and duplex stainless steel are used. Austenitic steels can be treated with processes such as sub-critical stress relief treatment, or slow cool, and full anneal, or quick cool.

Benefits of Stainless Steel Water Tanks

- Stainless steel water tanks are used to store water for commercial and domestic use.

- Stainless steel tanks are lightweight and easy to install.

- Stainless steel is non-reactive and non-corrosive.

- Stainless steel water tanks are economical.

- These water tanks are easy to clean and require low maintenance.

- There are less chances of leaks in these tanks.

- These tanks have high temperature resistance and zero moss growth.

- Stainless steel tanks are best suited for storing water, but are not suitable for storing other chemicals.

Choosing the Correct Stainless Steel Water Tank Company

To make sure you have the most productive outcome when purchasing stainless steel water tanks from a stainless steel water tank company, it is important to compare at least 4 to 5 manufacturers using our stainless steel water tank directory. Each stainless steel water tank company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each stainless steel water tank business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple stainless steel water tank companies with the same message.

55 Gallon Drums

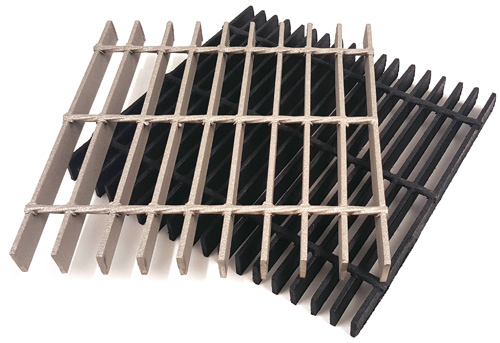

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services