Stainless steel water tanks hold water for a variety of purposes, including water treatment, and other factory processes. Even though these tanks are used to hold water, they still require frequent cleaning to remove mineral build-up and contaminants from the tanks. In the past, a solution of water, nitric acid, and hydrofluoric acid was used to clean the tanks. The problem with this cleaning method is that it removed small pieces of the metal from the tanks, causing the liquid to be classified as hazardous waste when the stainless steel water tanks were cleaned.

Since 2008, however, a new way to clean these water tanks has reduced the toxic nature of the process. This new process uses inductors below the tanks to help circulate the mixture. This enables companies to reduce the amount of acid used to clean the tanks and also lowers the necessary cleaning temperature by about 15 degrees. An acid purification system removes the metal particles from the cleaning solution as it cleans the inside of the tanks. The metal pieces are then mixed with lime and compressed so that the metal stays right where it belongs and will not leach out of the material. This makes the process of cleaning tanks environmentally safe because the metal particles will no longer cause contamination of the ground.

The process of cleaning water tanks using this method is long and expensive, but the process is well worth it in the end. When tanks are cleaned using this method, their corrosive chances are greatly reduced and nearly eliminated completely. This makes the lifespan of the water tanks increase dramatically, which can save factories money in the long run. Using the new environmentally friendly methods for cleaning the tanks also cuts down on chemical waste, which reduces the expense of disposing of hazardous materials.

55 Gallon Drums

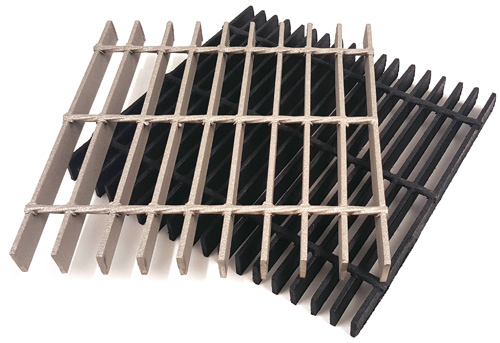

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services